Features

- Automated Tracking System

- Solar Panel directly facing the sun at all times

- Increased efficiency even on cloudy and dusty days

- Reduction of the annual energy consumption and generation of monthly savings

- A fully charged battery can power up to 60 LED lights and 30 fans for 6 hours under optimal conditions

- It is maintenance free, only daily cleaning of the solar panel is required

- The life of a good battery is almost 5 years, and for the rest of the components it is 10 years

- Recovery of initial investment cost of ₹35,000 per installation is within one year

Mechanism and Components

Today, most of the solar installations are fixed facing in a southward direction. This significantly reduces the electricity generated because the sun is constantly moving throughout the day, both in latitude and longitude. In a fixed system, the duration of the day during which the sun is directly facing a solar panel is very limited (not more than 3-5 hours). In order to increase the efficiency of the solar panel, I have designed a motorised solar tracker which rotates the solar panel in such a way that it always directly faces the sun. In doing so, a rotating solar panel generates a higher voltage and DC current compared to a fixed solar panel which faces in a southward direction.

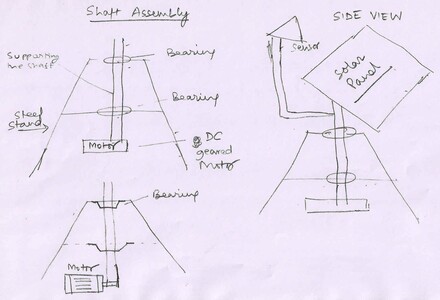

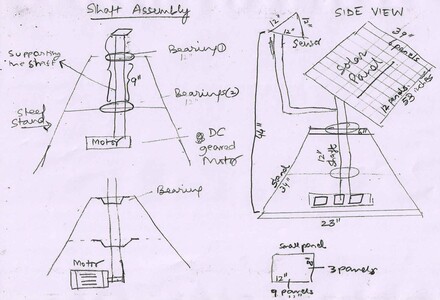

The MOTORISED SOLAR TRACKER is essentially a sun location sensor that rotates a DC motor, which in turn rotates the solar panel so that it directly faces the sun. There are two components of the Motorised Solar Tracker:Sun Location Sensor & Rotating Mechanism

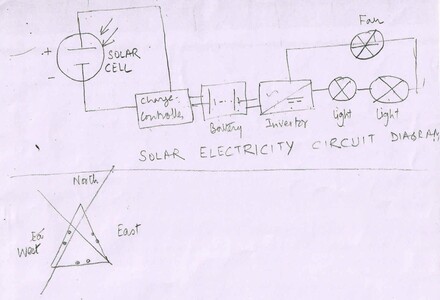

The Motorised Solar Tracker has three identical small solar panels of 5 Watts each (A, B, C). They are located at 60 degrees to each other and form the three sides of an equilateral triangle. The three solar panels (A,B,C) are wired to a single geared DC motor in a way such that they generate opposing voltage. In other words, voltage generated by one solar panel cancels out the voltage generated from another solar panel. Depending upon the position of the sun, one of the three (A,B,C) solar sensors generates higher voltage and current compared to the other two sensors, thereby rotating the DC motor in its direction.The DC motor in-turn rotates a steel shaft. A large electricity generating solar panel is mounted on the steel shaft. The steel shaft is supported by two bearings. The entire assembly is mounted on a steel frame.

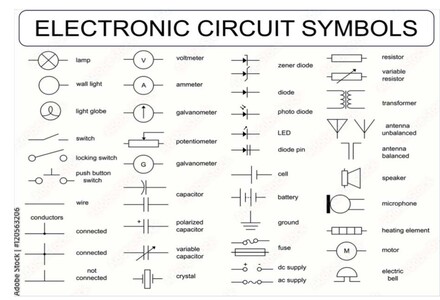

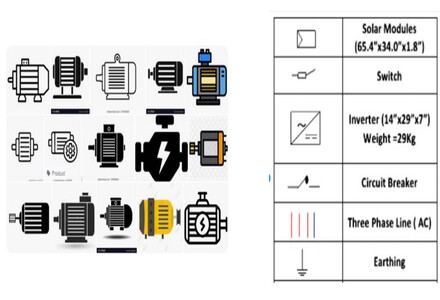

Electrical Circuit & Components

The large solar panel converts the sun’s solar energy into DC electrical current. The wires from the solar panel are connected to a 12-volt voltage regulator. The voltage regulator monitors the charging of a 12 volt / 80 Ampere-Hour battery. A voltmeter constantly shows the voltage of the battery and indicates its level of charge. Charge generated by the solar panel flows through the voltage regulator to charge the battery. Since the battery generates DC current, and all our appliances run on AC current, it needs to be converted to AC current. To achieve this, an invertor is connected to the battery. The invertor converts the 12 Volts DC of the battery into 230 volts AC current. This clean renewable solar energy generated can be used in our homes, offices and schools. Under optimal conditions, a fully charged battery can provide electricity upto 60 LED lights and 30 fans for 6 hours.

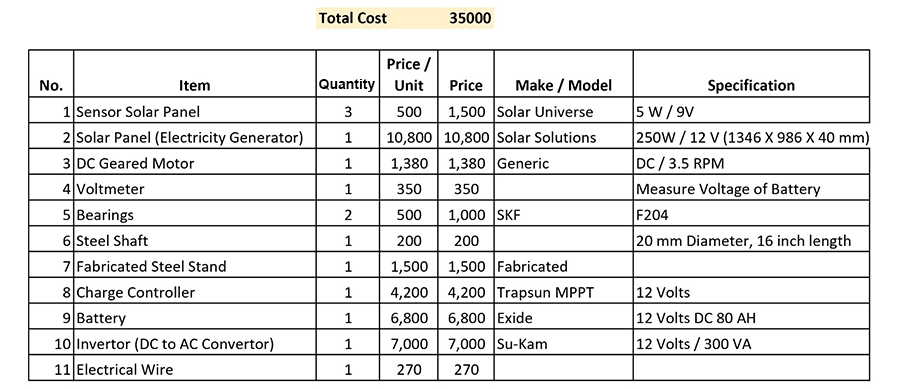

List of Items